Silica stone, a common non-metallic mineral material, has high hardness and brittleness. It has various applications, particularly in the construction industry, where it serves as a fundamental and crucial building block. Silica stone is also an essential raw material in glass production, used for manufacturing both ordinary and optical glass. To process silica stone ore, it needs to be crushed into uniformly sized particles. This requires the use of silica stone crushing equipment. Currently, there are various types of silica stone crushers available in the market, which can be categorized into coarse crushing, medium-fine crushing, and sand-making functions. The specific equipment includes:

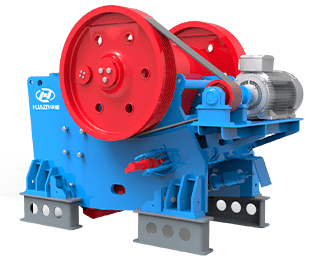

Coarse crushing - JC jaw crusher:

JC jaw crusher is a commonly used equipment for coarse crushing silica stone. It is suitable for primary crushing of large silica stone blocks, with a large feed inlet that can accommodate stones up to 1300mm in size. The crushing chamber is deep and free of dead zones, allowing for a large processing capacity. It can crush up to 1500 tons of silica stone per hour. The discharge particle size can be adjusted between 40-300mm, catering to different output requirements. The entire machine is made of highly wear-resistant materials, ensuring durability and longer equipment lifespan.

Medium-fine crushing - Hydraulic cone crusher:

Hydraulic cone crusher is a specialized medium-fine crushing equipment for silica stone. It is a high-power, high-crushing ratio, and high-productivity hydraulic crushing machine. It can crush up to 2500 tons of silica stone per hour, producing stone particles of various specifications, such as grade 6 and grade 7. The laminated crushing technology ensures regular-shaped finished stones with low powder content and high quality. There are various chamber types available, such as GPY single cylinder and HPY multi-cylinder, to meet different production needs.

Medium crushing - Impact crusher:

Impact crusher is a medium crushing equipment suitable for materials with medium hardness and brittleness. It utilizes high-speed rotating hammers to impact and grind the materials, as well as impact plates for further crushing and grinding, resulting in finely crushed particles. This equipment has a high crushing ratio and produces well-shaped cubic particles. The discharge particle size is adjustable. It is a high-yield, low-consumption, and structurally compact equipment.

Sand-making - PLS sand-making machine:

For sand-making purposes, the PLS sand-making machine can be equipped. This equipment uses the "stone-hitting-stone" crushing principle, combining both stone crushing and shaping functions. It can produce silica sand with a particle size of 0-5mm. The finished silica sand has a cubic shape, uniform and full particles, and good gradation. The equipment incorporates environmental-friendly design, with internal air circulation in the vortex chamber to effectively reduce dust emission and energy consumption. It is also equipped with soundproofing devices to minimize noise during operation.

The above introduction covers several commonly used crushing equipment for silica stone mining. In addition to the mentioned types, hammer crushers, roller crushers, and other equipment can also be used for silica stone crushing. Customers should choose the appropriate type and model of equipment based on the actual site conditions to improve crushing efficiency.