In industrial processes and materials handling, crushers play a key role in breaking large rocks, minerals and other materials into smaller, more manageable pieces. Among the many types of crushers, the vertical crusher stands out for its unique working principle and excellent efficiency in crushing various materials. Today we explore the complex working principles of vertical crushers and their importance in modern industry.

Understanding Vertical Crushers:

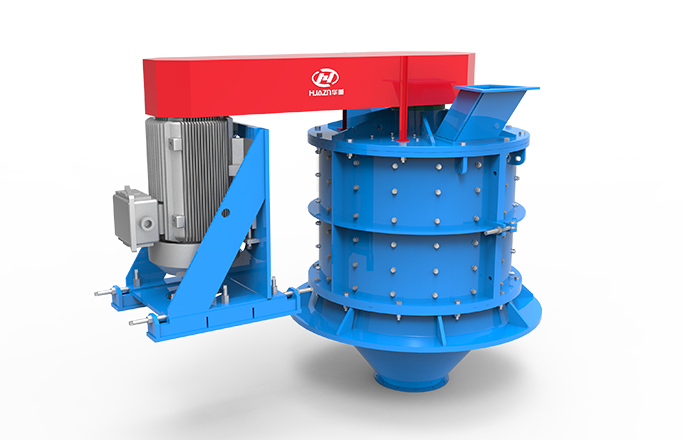

Vertical crushers, also known as vertical shaft impactors (VSI), are versatile machines that are commonly used in the mining, construction, and aggregate industries. They are designed to break down a wide range of materials, including rocks, ores, minerals, and even industrial byproducts, by applying high-speed impact forces. What sets them apart is their ability to produce precisely shaped end products, making them valuable tools for producing quality aggregates and finely crushed materials for various applications.

The Working Principle:

The fundamental principle behind the operation of a vertical crusher involves the use of a high-speed rotor with wear-resistant tips or anvils that accelerates materials to impact velocities. This rotor is usually enclosed in a crushing chamber, which is lined with a combination of wear-resistant materials to withstand the abrasive nature of the materials being processed.

When materials are fed into the crushing chamber from the top, they are subjected to the centrifugal force generated by the high-speed rotor. The materials are flung outwardly towards the anvils or tips lining the crushing chamber. As the materials collide with these anvils, intense impact forces are generated, causing them to break and fracture into smaller pieces.

Crucially, the impact forces occur not only between the materials and the anvils but also between the materials themselves. This secondary impact enhances the crushing process by ensuring that the particles undergo multiple fractures, leading to further reduction in size. As the materials continue to collide and interact, they are gradually reduced to the desired size and shape.

Advantages of Vertical Crushers:

Precise Shaping: Vertical crushers excel in producing well-shaped, cubical end products. This is especially crucial in industries like construction and infrastructure, where the quality of aggregates directly influences the properties of concrete and asphalt.

Efficient Crushing: The repeated impacts and collisions within the crushing chamber result in efficient and consistent reduction of material size. This efficiency can lead to substantial energy savings and increased throughput.

Minimal Wear Costs: The use of wear-resistant materials for the anvils and chamber lining helps reduce maintenance and replacement costs, contributing to overall operational economy.

Versatility: Vertical crushers can handle a wide range of materials, from hard and abrasive rocks to softer industrial byproducts. This versatility makes them suitable for various applications across different industries.

Low Contamination: Vertical crushers tend to produce lower levels of contaminants, such as fine dust, compared to some other crushing methods, which can be beneficial for specific applications and environmental concerns.

Conclusion:

Vertical crushers, with their ingenious working principle based on high-speed impact forces, have emerged as indispensable tools in the world of material processing and crushing. Their ability to efficiently produce well-shaped end products and handle a diverse range of materials makes them a preferred choice in industries such as mining, construction, and aggregates. As technology continues to advance, vertical crushers are likely to evolve even further, enhancing their efficiency and expanding their applications across various sectors.