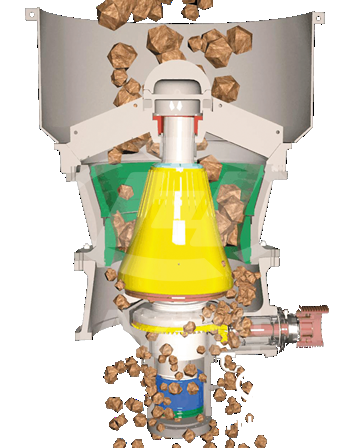

Hydraulic cone crushers may experience faults such as gear teeth damage, wear, and iron blockage during operation, which not only affects production but also leads to direct or indirect economic losses. To address such problems, it is necessary to analyze the causes and identify solutions and countermeasures. The factors that contribute to severe gear teeth damage and wear in hydraulic cone crushers are as follows:

Insufficient protection devices for the cone crusher.

Introduction of iron materials into the cone crusher exceeding the maximum size allowed, resulting in blockage.

Forcing the cone crusher to start with a heavy load after it has been blocked and stopped.

When iron blocks enter the cone crusher and cause a blockage, if they are not manually released in a timely manner, it forces the crusher to stop. The accumulation of material blocks at the feed opening of the cone crusher without cleaning them properly leads to the operator attempting multiple forceful starts with heavy loads in order to shorten the clearing time, resulting in repeated overloading and fatigue failure of the internal transmission of the cone crusher. Additionally, the ability to start the motor with a heavy load indicates insufficient protection devices.

Currently, the industry commonly employs the following methods to address gear teeth damage and wear in hydraulic cone crushers: improving equipment materials and hard alloy overlay welding. Based on the principle of the cone crusher and previous investigations into the causes of equipment failures, combined with the actual iron slag production line, the following strategies are proposed for adjustment and modification:

Install a permanent magnet hanging iron removal device on the conveyor belt that transports materials to the cone crusher, in addition to the iron removal performed by the head pulley. With these two iron removal steps, the entry of iron materials into the cone crusher can be effectively prevented.

Adjust the current of the protection device of the cone crusher to prevent forced starting or instantaneous tripping under heavy load conditions.

Regularly inspect the metal content inside the hydraulic oil tank on a monthly basis.

Improve operational procedures and strengthen supervision and assessment of iron blockage in the cone crusher, while reinforcing the joint responsibility assessment for production line managers and operators.